Ever wondered how do cooling towers work? Here we explain in full detail how does a cooling tower work, cooling tower working principles with example text, pictures and diagrams.

See the more detailed explanation of Cooling Towers systems, diagrams, pictures and principles below

- What Is A Cooling Tower

- How Do Cooling Towers Work Explanation

- Cooling Tower Working Priciple

- What Are Cooling Towers Used For

- Cooling Tower Applications

- Types Of Cooling Tower Systems

- How Cross Flow Cooling Towers Work

- How Counter Flow Cooling Towers Work

- How Forced Draft & Induced Draft Cooling Towers Work

- How Natural Draft Cooling Towers Work

- Factory Assembled Cooling Towers (FAP)

- Field-Erected Cooling Towers (FEP)

- How are cooling towers relate to Atmospheric Vortex Engines?

- Cooling Tower Parts & Functions

- Schedule Cooling Tower Services in Arizona

What Is A Cooling Tower? Answered

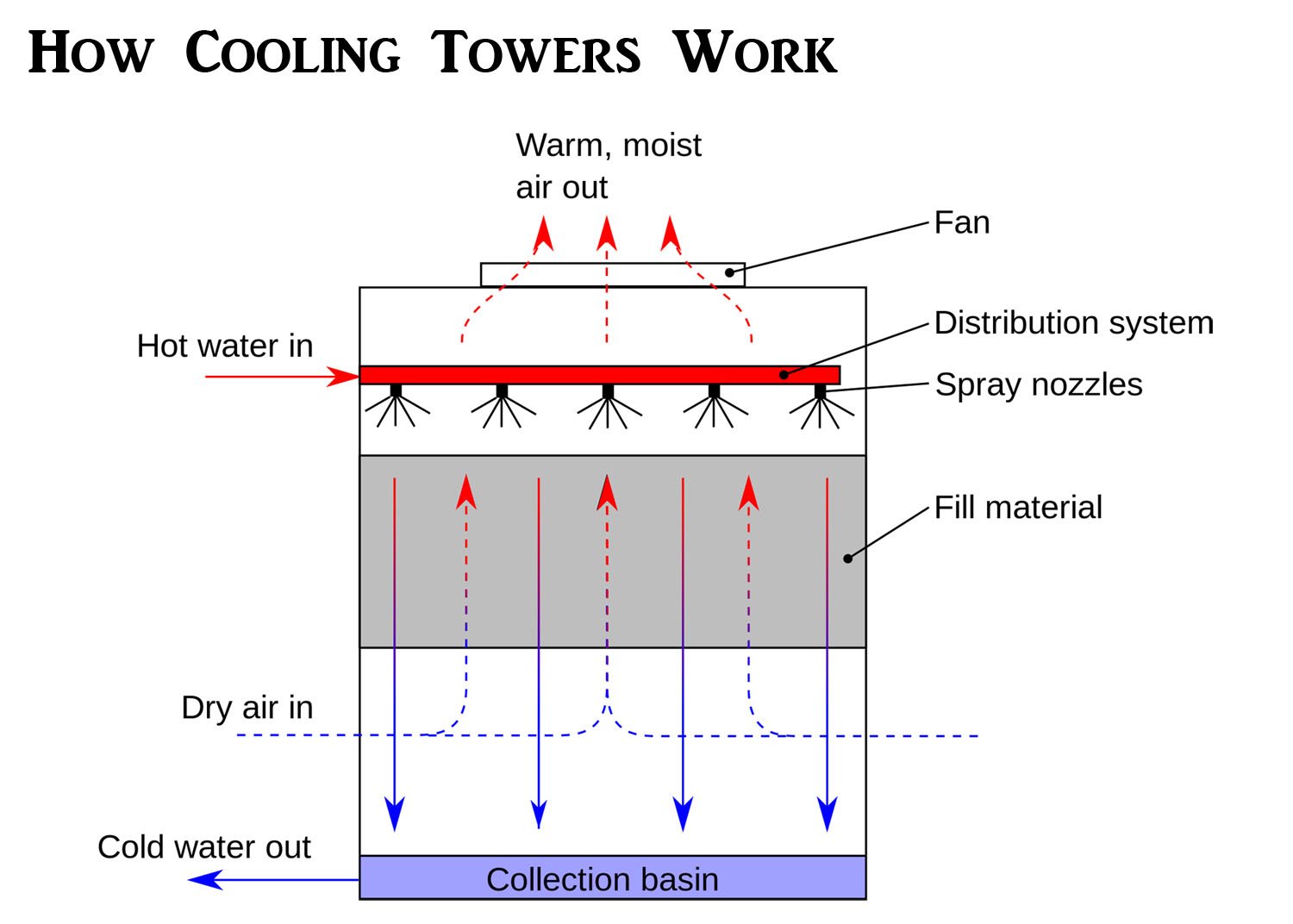

What is a cooling tower? Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. During the cooling tower working process, small volumes of water evaporate, lowering the temperature of the water that’s being circulated throughout the cooling tower.

In a short summary, the purpose of a cooling tower is to cool down water that gets heated up by industrial equipment and processes. Water comes in the cooling tower hot (from industrial process) and goes out of the cooling tower cold (back into the industrial process). Here we discover cooling tower functions and inner working of cooling towers for different applications.

How Do Cooling Towers Work Explanation

What are cooling towers? Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. During this process, small volumes of water evaporate, lowering the temperature of the water that’s being circulated throughout the cooling tower. In a short summary, a cooling tower cools down water that gets over heated by industrial equipment and processes.

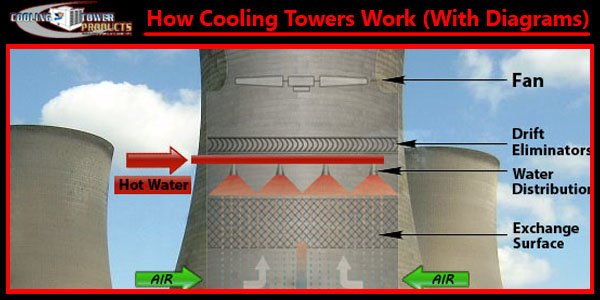

The hot water is usually caused by air conditioning condensers or other industrial processes. That water is pumped through pipes directly into the cooling tower. Cooling tower nozzles are used to spray the water onto to the “fill media”, which slows the water flow down and exposes the maximum amount of water surface area possible for the best air-water contact. The water is exposed to air as it flows throughout the cooling tower. The air is being pulled by an motor-driven electric “cooling tower fan”.

When the air and water come together, a small volume of water evaporates, creating an action of cooling. The colder water gets pumped back to the process/equipment that absorbs heat or the condenser. It repeats the loop over and over again to constantly cool down the heated equipment or condensers. For more knowledge and learning about cooling towers visit Cooling Tower Fundamentals by SPXCooling.

Cooling Tower Working Priciple

There are many different types of cooling towers but the cooling tower working principles stay pretty much the same. Most cooling towers work based on the principle of “evaporative cooling“.

What is Evaporative Cooling? Evaporative cooling is the process where warm water from an industrial process is pumped up to the top of the cooling tower where the water distribution system is. The water then gets distributed by cooling tower nozzles to the wet deck. At the same time, air is being drawn through the air-inlet louvers forcing water to evaporate. Evaporation causes the heat to be removed from the make up water. The hot air naturally rises out of the tire. Download the Working Principle Of Cooling Tower PDF.

What are cooling towers used for?

An HVAC cooling tower is used for disposing or rejecting heat from chillers. Air cooled chillers are less effecient than water cooled chillers due to rejection of heat from tower water near wet-bulb temperatures.

Cooling Tower Applications

Tradional HVAC heating and cooling systems are used in schools, large office buildings, and hospital. On the other hand, Cooling towers are much larger than tradional HVAC systems and are used to remove heat from cooling tower water systems in petroleum refineries, plants, natural gas processing plants, petrochemical plants, and other industrial processes and facilites.

Types Of Cooling Tower Systems

Cooling towers are usually designed for specific purposes. Not all cooling towers work for all applications or industrial processes. Here we help you understand the various types of cooling towers, there advantages/disadvantages and determine which cooling tower type is right for your industrial process. Check out the cooling tower list and parts list that provides an overview of cooling tower types to help you figure out which tower is right for your industrial application and what replacement parts you might need.

- Crossflow Cooling Towers

- Counterflow Cooling Towers

- Forced Draft & Induced Draft Cooling Towers Process

- Natural Draft & Fan Assisted Natural Draft Cooling Towers

- Factory Assembled Cooling Towers (FAP) Factory Assembled Product

- Field-Erected-Towers (FEP) Field Erected Product

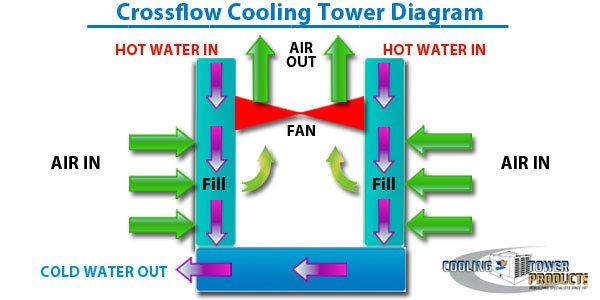

Crossflow Cooling Towers Flow Diagram

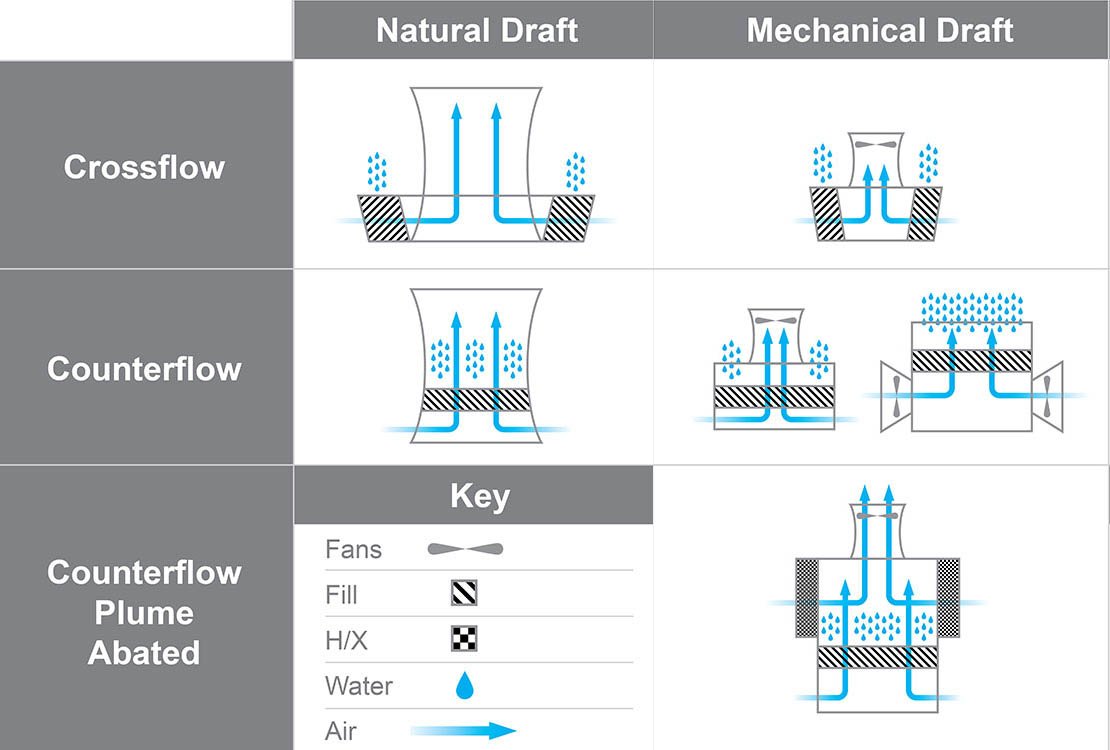

In crossflow cooling tower systems the water vertically flows through the fill media while the air horizontally flows across the falling water. That’s why they call it “crossflow” because the air and water cross paths or flows. Because of the crossing of flows, the air doesn’t need to pass through the distribution system. This permits the use of hot water flow via gravity and distribution basins on the top of the tower right above the fill media. The basins are a standard of crossflow cooling towers and are applied on all units.

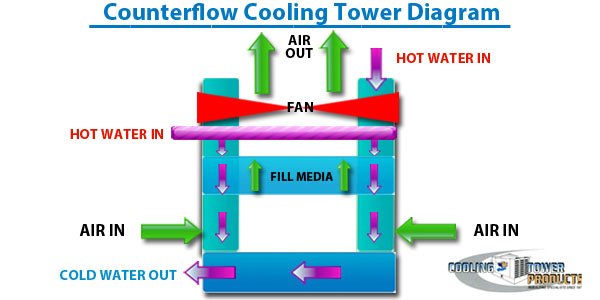

Counterflow Cooling Tower Diagram

Difference between crossflow and counterflow cooling towers: In counterflow cooling tower system processes, the air vertically flows upwards, counter to the water flow in the fill media. Due to the air flowing vertically, it’s not possible to use the basin’s gravity-flow like in crossflow towers. As a substitute, these towers use pressurized spray systems, usually pipe-type, to spray the water on top of the fill media. The pipes and cooling tower nozzles are usually spread farther apart so they will not restrict any air flow.

Forced Draft & Induced Draft Cooling Towers Process

Cooling tower fans are used on induced draft cooling towers to pull air up through the fill media. On forced draft cooling towers, the air is pushed/forced by blowers at the bottom of the air inlet louver.

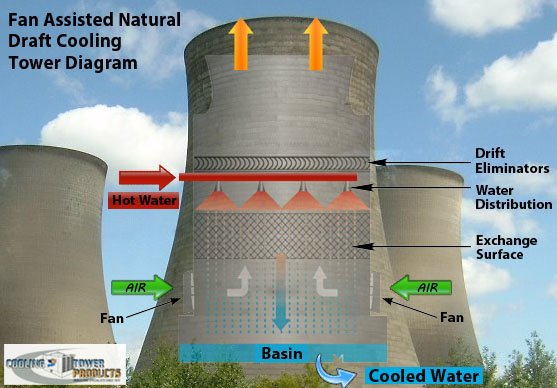

Natural Draft & Fan Assisted Natural Draft Cooling Towers

Factory Assembled Cooling Towers (FAP) Factory Assembled Product

These factory-assembled cooling tower systems come somewhat disassembled and are shipped in a few sections, ready for final assembly or field erection. Although, small factory-assembled cooling towers can be shipped intact. FAP cooling towers can be induced draft, crossflow, forced draft or counterflow depending on the application its need for. TCIA cooling towers are widely used for light industrial applications and HVAC.

Field-Erected-Towers (FEP) Field Erected Product

Field-erected cooling towers are usually constructed on the final destination site. The large FEP is usually prefabricated, marked by piece and shipped to the construction site for assembly. The cooling tower manufacturer usually handles all of the cooling tower construction process, final assembly, and labor involved. These type of towers can be counterflow or crossflow depending on the application. For heavy industrial applications or more power needed, field-erected cooling towers can be built to your exact specifications, structure, performance, plume abatement and drift.

How are cooling towers relate to Atmospheric Vortex Engines?

Cooling towers are normally required to transfer the heat from power plants to other process and then to the atmosphere. By using the wasted stream of heat that is intended for cooling towers to generate vortex provides the idea of pulling out additional energy by refusing the heat to the colder upper troposphere.

There is always potential to used wasted heat as additional fuel for atmospheric vortex engines whenever there is a cooling tower present or if there a abundant heat source available.

At the base of a natural waterspout, spray from warm sea water transfers sensible and latent heat to the rising air column. An atmospheric vortex engine simulates this natural heat transfer process using proven technology adapted from the cooling tower industry.

Although, there is a chance that you will need to make modifications to the tangential air inlet ducts.

These changes are required to make the air rise and create a spinning motion. It would only take a couple of minor modifications to convert cooling towers into atmospheric vortex engines.

Cooling Tower Parts & Products

This section has moved to a different post; View this post to see the list of cooling tower parts and functions.

Schedule Cooling Tower Services In Arizona

For specific information on how Cooling Tower Products can meet your cooling tower needs, contact your local Cooling Tower Products Representative or give us a call today at 800-733-1584. We offer cooling tower services in Arizona but can ship cooling tower parts worldwide.

This comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteSuper Blogs good to read it

ReplyDeleteWater Cooling Tower

Excellent Post thank for Update it

ReplyDeletepanel cooler

Water Cooling Tower

Maintaining industrial cooling towers isn’t an easy task if you don’t know much about them.

ReplyDeleteWith a little knowledge, you can make this task simple and efficient for yourself. By proper maintenance, you can enhance the performance and longevity of your chiller as well.

Just follow these tips to maintain your industrial chiller:

Regular Inspection

The fundamental method to maintain your industrial cooling tower is to inspect it regularly. From the gearbox to the water pump, you should do regular inspection to ensure there are no loose components.

Regular inspection will also allow you to spot corrosion, scaling and other similar adverse issues.

When you’ll find these issues before they escalate, you can get rid of them and keep your chiller in optimum condition.

Removing Deposits of Impurities

Impurities present in the water of the cooling tower gets collected in the system. They hinder the temperature of the chiller. Impure water requires more energy for changing its temperature.

So if you don’t use a cleaning system for your cooling tower, it’s necessary that you clean the tubes regularly and check the chiller for any sedimentation.

The collected impurities can damage the life of your chiller too. So you should remove those deposits regularly for keeping the tower free from any issues.

Read More: Importance of inspiring leadership in the HVAC industry by Tsur Ben David