Cavitation Explained and Illustrated

The phenomenon of cavitation consists in the disruption of continuity in the liquid where there is considerable local reduction of pressure. The formation of bubbles within liquids (cavitation) begins even in the presence of positive pressures that are equal to or close to the pressure of saturated vapor of the fluid at the given temperature.

Various liquids have different degrees of resistance to cavitation because they depend, to a considerable degree, upon the concentration of gas and foreign particles in the liquid.

Wear Mechanism

The mechanism of cavitation can be described as follows: Any liquid will contain either gaseous or vaporous bubbles, which serve as the cavitation nuclei. When the pressure is reduced to a certain level, bubbles become the repository of vapor or of dissolved gases.

The immediate result of this condition is that the bubbles increase rapidly in size. Subsequently, when the bubbles enter a zone of reduced pressure, they are reduced in size as a result of condensation of the vapors that they contain.

This process of condensation takes place fairly quickly, accompanied by local hydraulic shocks, the emission of sound, the destruction of material bonds and other undesirable phenomena. It is believed that reduction in volumetric stability in most liquids is associated with the contents of various admixtures, such as solid unwetted particles and gas-vapor bubbles, particularly those on a submicroscopic level, which serve as cavitation nuclei.

A critical aspect of the cavitation wear process is surface destruction and material displacement caused by high relative motions between a surface and the exposed fluid. As a result of such motions, the local pressure of the fluid is reduced, which allows the temperature of the fluid to reach the boiling point and small vapor cavities to form.

When the pressure returns to normal (which is higher than the vapor pressure of the fluid), implosions occur causing the cavity or vapor bubbles to collapse. This collapse of bubbles generates shock waves that produce high impact forces on adjacent metal surfaces and cause work hardening, fatigue and cavitation pits.

Thus, cavitation is the name given to a mechanism in which vapor bubbles (or cavities) in a fluid grow and collapse due to local pressure fluctuations. These fluctuations can produce a low pressure, in the form of vapor pressure of the fluid. This vaporous cavitation process occurs at approximately constant temperature conditions.

Cavitation Types

Two principal types of cavitation exist: vaporous and gaseous.

Vaporous cavitation is an ebullition process that takes place if the bubble grows explosively in an unbounded manner as liquid rapidly changes into vapor. This situation occurs when the pressure level goes below the vapor pressure of the liquid.

Gaseous cavitation is a diffusion process that occurs whenever the pressure falls below the saturation pressure of the noncondensable gas dissolved in the liquid. While vaporous cavitation is extremely rapid, occurring in microseconds, gaseous cavitation is much slower; the time it takes depends upon the degree of convection (fluid circulation) present.

Cavitation wear occurs only under vaporous cavitation conditions - where the shock waves and microjets can erode the surfaces. Gaseous cavitation does not cause surface material to erode.

It only creates noise, generates high (even molecular level cracking) temperatures and degrades the chemical composition of the fluid through oxidation. Cavitation wear is also known as cavitation erosion, vaporous cavitation, cavitation pitting, cavitation fatigue, liquid impact erosion and wire-drawing.

Cavitation wear is a fluid-to-surface type of wear that occurs when a portion of the fluid is first exposed to tensile stresses that cause the fluid to boil, then exposed to compressive stresses that cause the vapor bubbles to collapse (implode).

This collapse produces a mechanical shock and causes microjets to impinge against the surfaces, unifying the fluid. Any system that can repeat this tensile and compressive stress pattern is subject to cavitation wear and all the horrors accompanying such destructive activity.

Cavitation wear is similar to surface fatigue wear; materials that resist surface fatigue (hard but not brittle substances) also resist cavitation damage.

Cavitation Wear Process

Liquid is the medium that causes cavitation wear. Cavitation wear does not require a second surface; it requires only that high relative motion exists between the surface and the fluid. Such motion reduces the local pressure in the fluid. When the liquid reaches its boiling point and ebullition occurs, vapor bubbles form, which produces cavitation.

Each vapor cavity lasts a short time because almost any increase in pressure causes the vapor in the bubble to condense instantaneously and the bubble to collapse and produce a shock wave. This shock wave then impinges on adjacent metal surfaces and destroys the material bonds.

The shock wave first produces a compressive stress on the solid surface, and then when it is reflected, produces a tensile stress that is normal to the surface.

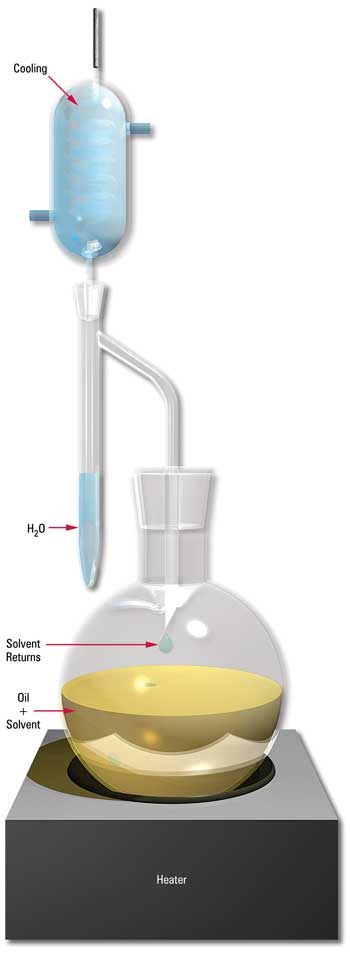

|

Figure 1. Vapor Bubble Collapse and the Birth of a Microjet

|

Figure 1 depicts the collapse of a vapor bubble and the birth of a microjet. Cavitation is generally found where a hydrodynamic condition, characterized by a sudden and gross change in hydrostatic pressure, exists. Because ebullition can occur the instant pressure drops, vapor bubbles form and collapse frequently and quickly.

Entrained air and dust particles in the fluid serve as nucleation sites for the formation of vapor cavities. These nuclei can be small gas-filled pockets in the crevices of the container or simply gas pockets on contaminant particles moving freely in the flow stream. Therefore, all confined fluids may contain sufficient impurities to produce cavitation.

Small voids near the surface or flow field, where minimum pressure exists, indicate that cavitation has begun. Once initiated, bubbles continue to grow as long as they remain in low-pressure regions. As the bubbles travel into high-pressure regions, they collapse, producing intense pressures and eroding any solid surfaces in the vicinity.

During the collapse, particles of liquid surrounding the bubble quickly move to its center. Kinetic energy from these particles creates local water hammers of high intensity (shock), which grow as the front progresses toward the center of the bubble.

Audible and Visual Detection

Equipment users can detect cavitation audibly, visually, by acoustical instrumentation, by machine vibration sensors, through sonoluminescence measurement or by a decrease or change in performance from that produced under single-phase flow conditions (for example, loss of flow, rigidity and response).

Under cavitating flow conditions, the wear rate can be many times greater than that caused by erosion and corrosion alone. Cavitation wear can destroy the strongest of materials - tool steels, stellites, etc. Such damage can occur rapidly and extensively.

The amount of damage that cavitation causes depends on how much pressure and velocity the collapsed bubbles create. As a result of this pressure and velocity, the exposed surface undergoes a variety of widely varying intensities.

Each imposition lasts only a short time; the impulse magnitudes and collapse times are greater for larger bubbles at given collapsing pressure differentials. Thus, the greater the tensile stress on the fluid (the lower the static pressure), the larger the bubbles, the more intense the cavitation and the more serious the damage.

The impulses that result when vapor bubbles form and collapse cause individual symmetrical craters and permanent material deformations when the collapse occurs next to the surface. Consequently, cavitation damage, like fatigue failure, has several periods of activity:

- Incubation period - microcracks nucleate around grain boundaries and inclusions due to both elastic and plastic deformation of the surface.

- Accumulation period - crack growth proceeds in relation to the degree of splitting, shearing and tearing action on the material.

- Steady-state period - the rate of crack nucleation and propagation becomes constant for the remainder of the exposure time.

In a fluid flow system (unlike an ultrasonic tank), vapor bubbles form where fluid tensile stresses (low pressures) occur, and vapor bubbles collapse in higher-pressure regions where compressive stresses can be imposed on the fluid.

So the region where damage occurs is often quite separate from the region in which cavities are created - often leading to an incorrect diagnosis of the problem. Cavitation wear is mechanical in nature and cannot occur without the application of the tensile and compressive stresses.

Cavitation Hot Spots

Many areas in hydraulic systems are prone to cavitation wear, such as:

- Downstream of control valves that have high pressure differentials,

- In the suction chambers of pumps where starved inlet conditions exist,

- In rapidly moving actuators (both linear and rotary types) where negative load conditions occur,

- In leakage paths (across seals, valve seats and spool lands) where high velocities cause pressure levels to drop below the vapor pressure of the fluid (a cavitation condition often referred to as wire-drawing) and

- In all devices where fluid flow is subjected to sharp turns, reduction in cross-sections with subsequent expansions (in cocks, flaps, valves, diaphragms) and other deformations.

Cavitation disturbs the normal operating conditions of fluid-type mechanical systems and destroys the surfaces of components. The process consists of cavities forming when pressures are low, the growth of subsequent bubbles as pressure stabilizes and finally the collapse of the bubbles when the cavities (gaseous or vaporous bubbles) are exposed to high-pressure.

Note that the pressure drop across the component is the driving force for cavitation wear. Figure 2 depicts the cavitation process that occurs in a gear pump and in a spool valve showing how cavities generate, grow and collapse in fluid-type components.

|

|

Figure 2. Cavitation Process in Hydraulic Components

|

Reducing Cavitation Wear

In cavitation wear, microcracks propagate to the point where the material can no longer withstand the impulse load that the imploding vapor bubbles impose. Therefore, particles finally break off and enter the system.

As with any fatigue failure, microcracks first form at stress risers (notches, tears, undercuts, welding defects, etc.) or at heterogeneous areas of the material (such as at the directionality of metal flow, inclusions, and decarburized sections).

Therefore, a rough surface is prone to cavitation wear and because pittings and a rough profile characterize the cavitation damage, the damage increases as the surface becomes rougher.

The most basic means of combating cavitation wear is to minimize the tensile stress on the fluid. In other words, the equipment users must lower the level of refraction or vacuum conditions in zones of possible cavitation. In particular, the following steps may be appropriate:

- Increase the pressure level at the outlet of throttling valves.

- Increase the inlet pressure at the pump suction port by supercharging the pump inlet.

- Use anticavitation checks on negative load actuator applications.

- Reduce the water content of the fluid to eliminate the possibility of wire-drawing (water has a higher vapor pressure than oil) across valve seats and dynamic seals.

- Use a fluid with a low vapor pressure.

- Select a pump with good filling characteristics as opposed to a starved inlet configuration.

- Use a fluid with low viscosity or increase the fluid temperature.

In many cases, design engineers can minimize cavitation damage by properly selecting fabrication materials. For example, stainless steel may be selected instead of aluminum (Figure 3) and use hard facing with a cavitation-resistant alloy on the exposed surface. Rubber and other elastomeric coatings have also helped minimize cavitation wear. Despite their low resistance to cavitation, these surfaces reflect the shock wave without causing intense damage.

|

Figure 3. Order of Relative Cavitation Resistance of Materials

|

Cavitation Particles

The size of the particles generated by cavitation wear is a function of the Brinell hardness of the exposed material. The largest particles occur during the accumulation period. The slopes of the cumulative particle size distribution curves increase as the strain energy of the material increases. The average size of the particles produced by cavitation decreases as the cavitation intensity increases.

Precursors of Cavitation

When investigating a cavitation problem in a fluid system, you must identify all possible sources of low pressure (vacuum), high temperature (heat), and locations where air might be ingressing. The following list should serve as a guideline for identifying low pressure areas in a fluid system:

- Pump suction - improper suction line hydraulics (flow limiting conditions).

- Valve orifice effect - vortexes from high velocity jet in control valve flow passages.

- Submerged jet - a jet extending into unbounded flow areas where regions of low pressure are created.

- Negative loads on motors and cylinders - externally driven actuator loads create low pressure in actuator.

- Pressure surges and water hammer - the rarefaction portion of pressure waves are capable of creating negative pressure regions in the line.

- High altitude effect - low atmospheric pressure subjects the suction line to pressure that may prove inadequate in filling the pumping chambers.

Sources of Heat that Lead to Cavitation

The sources of heat that contribute to excessively high temperatures and cavitation in system fluid include the following:

- High ambient temperature

- Poor mechanical efficiency of pumps and motors

- Turbulent flow conditions in conduits

- Heat of vaporization in cavitating flow

- Heat of compression in aerated flow

- High pressure drops across control orifices

- Severe operational duty cycle

- Major flow restrictions in all parts of the fluid circulating system

- Poor cooling or lack of heat transfer

- High friction from rough surfaces and abrasive action

Possible Air Ingression Locations to Check

As far as air ingression points of a system are concerned, you should carefully scrutinize these locations when serious cavitation is occurring:

Reservoirs - sites where mechanical (agitation) type air entrainment occurs, swirling fluid exists, fluid impingement on liquid or solid surfaces, pressurized reservoir conditions, cyclonic flow at pump suction port, critical altitude (angled reservoir) occurring during operation that exposes the pump suction port to the atmosphere, jostling of the fluid due to movement over rough terrain and/or low reservoir fluid level that expose the pump suction port to the atmosphere.

Pump - small diameter conduits and/or ports, restrictive flow passages, flow diversions, and/or long suction line conditions, poor pump filling characteristics (restrictive internal flow passages, high pumping speed, overly large flow displacement); altitude too high to provide sufficient reservoir pressure to supply the pump at rated flow conditions; inadequate suction head to lift fluid to pump inlet level (that is, elevation between fluid level and pump intake too great), insufficient suction head to accelerate reservoir fluid to the rated flow conditions of the pump (non-responsive to the pump displacement demands).

Valves - jets discharging from orifices into limited flow space, streamline flow through channels terminating in chambers where low pressure is at the downstream walls of the valve, and/or throttle valves discharging into a low pressure (return line) conduit.

Actuators (extended seals) - air passing rod seals, air desorption existing, and/or vaporous cavities forming when negative loading occurs due to external inertial loads.

Motors (shaft seals) - air passing seals and gaseous/vaporous cavitation occurring when negative loading exists due to a flywheel effect.

Accumulator - air/gas leaking past worn piston seal, ruptured diaphragm, or torn bladder.

Filter - air passing external seals in suction line filters or internal flow restrictions causing air desorption.

Conduit connectors (hose couplings, tube fittings, and manifold seals) - air passing connector sealing surfaces that vibration and thermal expansion and contraction effects have loosened.

Conduit - rough walls, pinched down flow sections, or protrusions in flow stream.