---- Forwarded by Dr Amarnath Giri/TS/KKD/NFCL/NAGARJUNA on 06/28/2019 11:43 AM -----

Dear Sir ,

Wish you Very good evening as per our FRUITFUL discussion regarding COC.

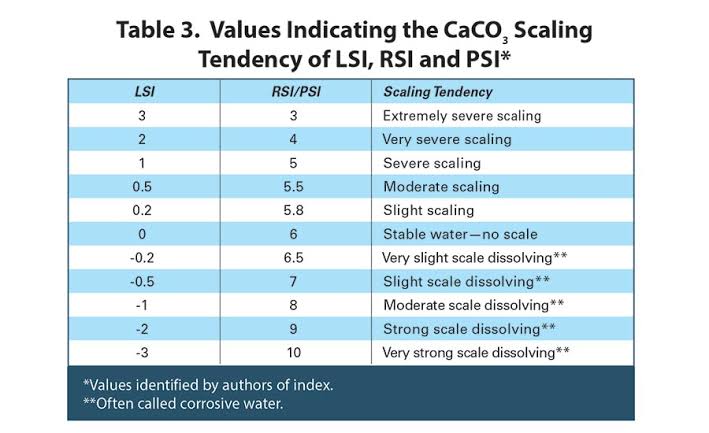

The LSI is probably the most widely used indicator of cooling water scale potential. It is purely an equilibrium index and deals only with the thermodynamic driving force for calcium carbonate scale formation and growth.

Cycles of concentration

Cycles of concentration

| From: | Dr Amarnath Giri/TS/KKD/NFCL/NAGARJUNA | |

| To: | J Kanaka Prasad/PROD/KKD/NFCL/

| |

| Date: | 02/27/2019 04:27 PM | |

| Subject: | Cycles of concentration : When the solubility of these minerals have been exceeded they can precipitate out as mineral solids and cause fouling and heat exchange problems in the heat exchangers and/or in the cooling tower itself. |

Wish you Very good evening as per our FRUITFUL discussion regarding COC.

The LSI is probably the most widely used indicator of cooling water scale potential. It is purely an equilibrium index and deals only with the thermodynamic driving force for calcium carbonate scale formation and growth.

The cycles of concentration represent the accumulation of dissolved minerals in the recirculating cooling water. Blowdown of a portion of the circulating water (from the tower basin) is the principal means of controlling the buildup of these minerals.

The chemistry of the makeup water including the amount of dissolved minerals can vary widely. Makeup waters low in dissolved minerals such as those from surface water supplies (lakes, rivers etc.) tend to be aggressive to metals (corrosive). Makeup waters from ground water supplies (wells) are usually higher in minerals and tend to be scaling (deposit minerals).

As the cycles of concentration increase, the water may not be able to hold the minerals in solution. When the solubility of these minerals have been exceeded they can precipitate out as mineral solids and cause fouling and heat exchange problems in the heat exchangers and/or in the cooling tower itself. . The temperatures of the recirculating water, piping and heat exchange surfaces determine if and where minerals will precipitate from the recirculating water. Often a professional water treatment consultant will evaluate the makeup water and the operating conditions of the cooling tower and recommend an appropriate range for the cycles of concentration. The use of water treatment chemicals, pretreatment such as water softening, pH adjustment, and other techniques can affect the acceptable range of cycles of concentration.

Concentration cycles in the majority of cooling towers usually range from 3 to 7. In the United States the majority of water supplies are well waters and have significant levels of dissolved solids. On the other hand, one of the largest water supplies in the United States (located in the city of New York) has water that is quite low in minerals and cooling towers in that city are often allowed to concentrate to 7 or more cycles of concentration.

Besides treating the circulating cooling water in large industrial cooling tower systems to minimize scaling and fouling, the water should be filtered and also be dosed with biocides and algacides to prevent growths that could interfere with the continuous flow of the water. Corrosion inhibitors may also be used, but caution should be taken to meet local environmental regulations as some inhibitors use chromates which are toxic.

The chemistry of the makeup water including the amount of dissolved minerals can vary widely. Makeup waters low in dissolved minerals such as those from surface water supplies (lakes, rivers etc.) tend to be aggressive to metals (corrosive). Makeup waters from ground water supplies (wells) are usually higher in minerals and tend to be scaling (deposit minerals).

As the cycles of concentration increase, the water may not be able to hold the minerals in solution. When the solubility of these minerals have been exceeded they can precipitate out as mineral solids and cause fouling and heat exchange problems in the heat exchangers and/or in the cooling tower itself. . The temperatures of the recirculating water, piping and heat exchange surfaces determine if and where minerals will precipitate from the recirculating water. Often a professional water treatment consultant will evaluate the makeup water and the operating conditions of the cooling tower and recommend an appropriate range for the cycles of concentration. The use of water treatment chemicals, pretreatment such as water softening, pH adjustment, and other techniques can affect the acceptable range of cycles of concentration.

Concentration cycles in the majority of cooling towers usually range from 3 to 7. In the United States the majority of water supplies are well waters and have significant levels of dissolved solids. On the other hand, one of the largest water supplies in the United States (located in the city of New York) has water that is quite low in minerals and cooling towers in that city are often allowed to concentrate to 7 or more cycles of concentration.

Besides treating the circulating cooling water in large industrial cooling tower systems to minimize scaling and fouling, the water should be filtered and also be dosed with biocides and algacides to prevent growths that could interfere with the continuous flow of the water. Corrosion inhibitors may also be used, but caution should be taken to meet local environmental regulations as some inhibitors use chromates which are toxic.

No comments:

Post a Comment