The 50 Major Engineering Failures (1977-2007) Part-3

April 28, 2008

List of Engineering Failures

Contributed by Material Failures, Corrosion, Design Flaw, and

Construction Defect in Oil and Gas Production Facilities, Hydrocarbon

Processing, and Oil and Gas Distribution

(Part 3 of 5) - Muhammad Abduh (abduh@reksolindo.co.id)

24. Martinez California US – January 27, 1997 (Creep, Refinery, USD 80,000,000/82,000,000)

An effluent line from reactor in hydrocracker unit failed at pipe body leading to fire and explosion. Released hydrocarbon were auto-ignited because high temperature of the line seconds before explosion. Analysis of the failed pipe noted that the failure mechanism was creep above 1300 °F which expanded the 12-inches pipe circumferentially by 5-inches causing localized bulge in the pipe prior to rupture. (Source)

25. Yokkaichi Mie Japan – May 2, 1997 (Erosion-Corrosion, Petrochemical Plant)

A T-joint of high-pressure piping for recycle ethylene gas failed and lead to explosion. The explosion occurred by the ignition of released ethylene gas by static electricity. Failure was contributed by erosion corrosion event by the evidence of presence of water and a local vortex accompanying a high-speed flow. Erosion corrosion caused a local thinning and the pipe could no longer withstand internal pressure. (Source)

26. Visakhapatnam India – September 14, 1997 (Pipe Leaking, Refinery,50 killed, 27 injured, 100 evacuated, USD 64,000,000)

Piping in loading port and storage tank leaked. The heavier than air gas spread at ground level and ignited. A vapor cloud explosion to this refinery became more severe due to lack of anti-fire foam. The plant layout in which the LPG tanks and pipelines were very close to several administrative building caused large number of fatalities. (Source 1, 2)

27. St Helena California US – December 2, 1997( Corrosion-Pitting, Fuel Pipeline, USD 14,000,000/17,000,000)

36-inches pipe failed with up to 10,000 barrels of gasoline spilled. Both uniform and pit corrosion were found at the failed segment. The pipe was carbon steel with SMYS 52 kpsi, designed at operating pressure 584 psi and maximum allowable pressure at 758 psi. The pressure at the point of failure was 345 psi. (Source)

28. Bintulu Serawak Malaysia -December 25, 1997 (Gas Processing Plant, High Temperature Failure, 12 injured, USD 275,000,000/294,000,000)

Incipient combustion event at air separation unit (ASU) at a gas-to- liquid (GTL) plant and with the presence of liquid oxygen caused the explosive burning of the aluminum heat exchanger elements. The elements ruptured explosively. The plant was shut down for several months for repair. (Source)

29. Longford Victoria Australia -September 25, 1998 (Brittle Fracture, Gas Processing Plant, 2 killed, 8 injured, USD 160,000,000/171,000,000)

Figure Showing GP 905 Heat Exchanger of Longford Gas Plant

Operation error of a bypass valve allowed condensate to spill over into other parts of the system eventually causing the failure of warm oil pumps. Temperature of a heat exchanger decreased sufficiently to lead to material brittle transition. Operator then made error of restarting the warm oil flow which caused the heat exchanger to fracture. An initial release approximately 22,000 pounds of hydrocarbon vapor exploded and made the plant burned for two and a half days. Victoria was said to be in chaos for 19 days. The accident caused a large socio-economic excess. There were 10,000 litigants signed a class action suit that made it a largest class action in Australian legal history. (Source 1,2,3)

30. Berre l’Etang France – October 6, 1998 (Corrosion, Refinery,USD 22,000,000/23,000,000)

A pipe failed due to corrosion and released gas ignited when contacting hot process line. The fire caused the failure of kerosene air cooler and adding more fuel too the fire. The fire created severe damage to 127,000 barrels-per-day crude unit and a 17,000 barrels-per-day reformer. Corrosionwas largely associated with the presence of more corrosive naphtanic acid. (Source)

31. Idjerhe Niger Delta Nigeria – October 17, 1998 (Pipe Leaking,Fuel Pipeline,100 killed)

Pipe leaked a day before the explosion. Large number of victim due to people from surrounding pipeline right of way gathers to fetch the fuel spill. The pipe that burst runs parallel to River Ethiope and has two major foot paths to it from the road. The pipeline was laid in the early 1970. The area is actively cultivated by the local people. Next to the buried fuel pipe is a gas pipeline about 15 meters apart. Poor pipeline maintenance was associated with the leaking. (Source)

32. Knoxville Tennesse US – February 9, 1999 (Brittle Fracture, 15 evacuated, USD 8,100,000)

Figure Showing Circumferential Crack of Knoxville Pipeline (NTSB US)

A pipe failed releasing 53,500 barrels of diesel fuel. The pipe was 10-inches in diameter, API 5L X-42 SMYS 42 kpsi, electric resistance weld (ERW) carbon steel and with 0.25 inches in thickness. Circumferential crack was found at the failed segment. The possible cause for cracking was noted by the low toughness of the manufactured pipe material. The pipe was constructed in 1962 when there was no adequate toughness requirement from available pipe code and design. National Transportation Safety Board had already

given recommendation for toughness requirement to Department of Transportation Research and Special Administration Agency (RSPA) when a similar failure occurred in 1994 in New Jersey. In 2000 responding the request from RSPA, American Petroleum Institute (API) added minimum toughness requirements to API Specification 5L. (Source)

33. Martinez Caifornia US – February 23, 1999 (Corrosion, 4 killed, 1 injured)

Leakage and fire occurred and originated from a heat exchanger. The heat exchganer condensed vapor from a high temperature and high pressure separator at the outlet of the reactor of a fuel oil hydro- desulfurization unit. One heat transfer tube of the fin-fan cooler was was corroded. Corrosion was caused by inadequate re-design of heat exchanger changing service. (Source)

34. Winchester Kentucky US – January 27, 2000 (Crude Oil Pipeline, Fatigue, USD 7,100,000)

Figure showing Winchester fatigue cracked pipeline

A 24-inches pipeline ruptured and released 11,644 barrels of crude oil. Laboratory examination of the failed segment showed a transgranular cracks that had the appearance of typical fatigue progression. The fatigue cracking was caused by a dent in pipe with the combination of fluctuating pressures within the pipe producing high local stress in the pipe wall. (Source)

35. Hunt Texas US- March 3, 2000 (Corrosion, Fuel Pipeline, USD 40,000,000)

28-inches in diameter pipe failed due to external corrosion causing 13,400 barrels of gasoline spill. The failed segment was submerged below ground. Leaking originated at the body pipe. The material was carbon steel with SMYS 52 kpsi, designed at 751 psi to maximum 955 psi. The pressure at the failed segment was 705 psi. (Source)

36. Prince Georges US – April 7, 2000 (Pipe Leaking, Fuel Pipeline, USD 50,000,000/ 57,000,000)

A submerged pipe carrying refined petroleum product failed. At the time of failure, the pipe was 27 years in operation, has SMYS 1.61 kpsi and designed pressured at 550 psi/1600 psi. This pipe failure caused the largest loses of fuel spill that recorded by US DOT PHMSA. A report said that no corrosion significantly susceptible for the cause of failure neither in the weld. (Source)

37. Mina Al-Ahmadi Kuwait – June 25, 2000 (Erosion-Corrosion, Refinery, 5 killed, 50 injured, USD412,000,000/ 433,000,000)

FIgure Showing Mina Al-Ahmadi Refinery Exploded

A condensate line between a NGL plant and refinery failed. The operators were trying to isolate the leaking line and the explosion occurred. Three crude units and two reformers were damaged. Accident to this national biggest oil refinery made an enormous economic looses and excess in sociopolitic when Kuwait oil minister offers resignation. The failed pipe was an aging pipe that suffered erosion-corrosion and slipped through the inspection and maintenance. (Source)

38. Carlsbad New Mexico US – August 19, 2000 (Corrosion-Pitting, Gas Pipeline, 12 killed, USD 100,000,000)

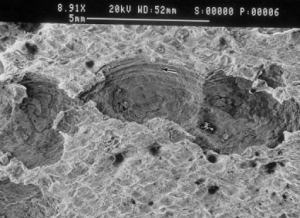

Figure showing micrograph corroded-pit of Carlsbad Pipeline

A 50-years, 30-inch-diameter natural gas transmission pipeline ruptured. The release gas ignited and burned for 55 minutes. Investigation of the failed segment revealed severe internal pit-corrosion as major contributing cause of the failure. At the time of failure the pipe withstand 80% of maximum design pressure. National Transportation Safety recommended amendment in 49 Code of Federal Regulations (CFR) Part 192 to require that new or replaced pipelines be designed and constructed with features to mitigate internal corrosion and to National Association of Corrosion Engineer (NACE) to establish more guidelines to control internal corrosion . Pipeline operator spend USD 15,500,000 for legal fine and USD 86,000,000 for pipeline modifications. (Source)

(Part 3 of 5) - Muhammad Abduh (abduh@reksolindo.co.id)

24. Martinez California US – January 27, 1997 (Creep, Refinery, USD 80,000,000/82,000,000)

An effluent line from reactor in hydrocracker unit failed at pipe body leading to fire and explosion. Released hydrocarbon were auto-ignited because high temperature of the line seconds before explosion. Analysis of the failed pipe noted that the failure mechanism was creep above 1300 °F which expanded the 12-inches pipe circumferentially by 5-inches causing localized bulge in the pipe prior to rupture. (Source)

25. Yokkaichi Mie Japan – May 2, 1997 (Erosion-Corrosion, Petrochemical Plant)

A T-joint of high-pressure piping for recycle ethylene gas failed and lead to explosion. The explosion occurred by the ignition of released ethylene gas by static electricity. Failure was contributed by erosion corrosion event by the evidence of presence of water and a local vortex accompanying a high-speed flow. Erosion corrosion caused a local thinning and the pipe could no longer withstand internal pressure. (Source)

26. Visakhapatnam India – September 14, 1997 (Pipe Leaking, Refinery,50 killed, 27 injured, 100 evacuated, USD 64,000,000)

Piping in loading port and storage tank leaked. The heavier than air gas spread at ground level and ignited. A vapor cloud explosion to this refinery became more severe due to lack of anti-fire foam. The plant layout in which the LPG tanks and pipelines were very close to several administrative building caused large number of fatalities. (Source 1, 2)

27. St Helena California US – December 2, 1997( Corrosion-Pitting, Fuel Pipeline, USD 14,000,000/17,000,000)

36-inches pipe failed with up to 10,000 barrels of gasoline spilled. Both uniform and pit corrosion were found at the failed segment. The pipe was carbon steel with SMYS 52 kpsi, designed at operating pressure 584 psi and maximum allowable pressure at 758 psi. The pressure at the point of failure was 345 psi. (Source)

28. Bintulu Serawak Malaysia -December 25, 1997 (Gas Processing Plant, High Temperature Failure, 12 injured, USD 275,000,000/294,000,000)

Incipient combustion event at air separation unit (ASU) at a gas-to- liquid (GTL) plant and with the presence of liquid oxygen caused the explosive burning of the aluminum heat exchanger elements. The elements ruptured explosively. The plant was shut down for several months for repair. (Source)

29. Longford Victoria Australia -September 25, 1998 (Brittle Fracture, Gas Processing Plant, 2 killed, 8 injured, USD 160,000,000/171,000,000)

Figure Showing GP 905 Heat Exchanger of Longford Gas Plant

Operation error of a bypass valve allowed condensate to spill over into other parts of the system eventually causing the failure of warm oil pumps. Temperature of a heat exchanger decreased sufficiently to lead to material brittle transition. Operator then made error of restarting the warm oil flow which caused the heat exchanger to fracture. An initial release approximately 22,000 pounds of hydrocarbon vapor exploded and made the plant burned for two and a half days. Victoria was said to be in chaos for 19 days. The accident caused a large socio-economic excess. There were 10,000 litigants signed a class action suit that made it a largest class action in Australian legal history. (Source 1,2,3)

30. Berre l’Etang France – October 6, 1998 (Corrosion, Refinery,USD 22,000,000/23,000,000)

A pipe failed due to corrosion and released gas ignited when contacting hot process line. The fire caused the failure of kerosene air cooler and adding more fuel too the fire. The fire created severe damage to 127,000 barrels-per-day crude unit and a 17,000 barrels-per-day reformer. Corrosionwas largely associated with the presence of more corrosive naphtanic acid. (Source)

31. Idjerhe Niger Delta Nigeria – October 17, 1998 (Pipe Leaking,Fuel Pipeline,100 killed)

Pipe leaked a day before the explosion. Large number of victim due to people from surrounding pipeline right of way gathers to fetch the fuel spill. The pipe that burst runs parallel to River Ethiope and has two major foot paths to it from the road. The pipeline was laid in the early 1970. The area is actively cultivated by the local people. Next to the buried fuel pipe is a gas pipeline about 15 meters apart. Poor pipeline maintenance was associated with the leaking. (Source)

32. Knoxville Tennesse US – February 9, 1999 (Brittle Fracture, 15 evacuated, USD 8,100,000)

Figure Showing Circumferential Crack of Knoxville Pipeline (NTSB US)

A pipe failed releasing 53,500 barrels of diesel fuel. The pipe was 10-inches in diameter, API 5L X-42 SMYS 42 kpsi, electric resistance weld (ERW) carbon steel and with 0.25 inches in thickness. Circumferential crack was found at the failed segment. The possible cause for cracking was noted by the low toughness of the manufactured pipe material. The pipe was constructed in 1962 when there was no adequate toughness requirement from available pipe code and design. National Transportation Safety Board had already

given recommendation for toughness requirement to Department of Transportation Research and Special Administration Agency (RSPA) when a similar failure occurred in 1994 in New Jersey. In 2000 responding the request from RSPA, American Petroleum Institute (API) added minimum toughness requirements to API Specification 5L. (Source)

33. Martinez Caifornia US – February 23, 1999 (Corrosion, 4 killed, 1 injured)

Leakage and fire occurred and originated from a heat exchanger. The heat exchganer condensed vapor from a high temperature and high pressure separator at the outlet of the reactor of a fuel oil hydro- desulfurization unit. One heat transfer tube of the fin-fan cooler was was corroded. Corrosion was caused by inadequate re-design of heat exchanger changing service. (Source)

34. Winchester Kentucky US – January 27, 2000 (Crude Oil Pipeline, Fatigue, USD 7,100,000)

Figure showing Winchester fatigue cracked pipeline

A 24-inches pipeline ruptured and released 11,644 barrels of crude oil. Laboratory examination of the failed segment showed a transgranular cracks that had the appearance of typical fatigue progression. The fatigue cracking was caused by a dent in pipe with the combination of fluctuating pressures within the pipe producing high local stress in the pipe wall. (Source)

35. Hunt Texas US- March 3, 2000 (Corrosion, Fuel Pipeline, USD 40,000,000)

28-inches in diameter pipe failed due to external corrosion causing 13,400 barrels of gasoline spill. The failed segment was submerged below ground. Leaking originated at the body pipe. The material was carbon steel with SMYS 52 kpsi, designed at 751 psi to maximum 955 psi. The pressure at the failed segment was 705 psi. (Source)

36. Prince Georges US – April 7, 2000 (Pipe Leaking, Fuel Pipeline, USD 50,000,000/ 57,000,000)

A submerged pipe carrying refined petroleum product failed. At the time of failure, the pipe was 27 years in operation, has SMYS 1.61 kpsi and designed pressured at 550 psi/1600 psi. This pipe failure caused the largest loses of fuel spill that recorded by US DOT PHMSA. A report said that no corrosion significantly susceptible for the cause of failure neither in the weld. (Source)

37. Mina Al-Ahmadi Kuwait – June 25, 2000 (Erosion-Corrosion, Refinery, 5 killed, 50 injured, USD412,000,000/ 433,000,000)

FIgure Showing Mina Al-Ahmadi Refinery Exploded

A condensate line between a NGL plant and refinery failed. The operators were trying to isolate the leaking line and the explosion occurred. Three crude units and two reformers were damaged. Accident to this national biggest oil refinery made an enormous economic looses and excess in sociopolitic when Kuwait oil minister offers resignation. The failed pipe was an aging pipe that suffered erosion-corrosion and slipped through the inspection and maintenance. (Source)

38. Carlsbad New Mexico US – August 19, 2000 (Corrosion-Pitting, Gas Pipeline, 12 killed, USD 100,000,000)

Figure showing micrograph corroded-pit of Carlsbad Pipeline

A 50-years, 30-inch-diameter natural gas transmission pipeline ruptured. The release gas ignited and burned for 55 minutes. Investigation of the failed segment revealed severe internal pit-corrosion as major contributing cause of the failure. At the time of failure the pipe withstand 80% of maximum design pressure. National Transportation Safety recommended amendment in 49 Code of Federal Regulations (CFR) Part 192 to require that new or replaced pipelines be designed and constructed with features to mitigate internal corrosion and to National Association of Corrosion Engineer (NACE) to establish more guidelines to control internal corrosion . Pipeline operator spend USD 15,500,000 for legal fine and USD 86,000,000 for pipeline modifications. (Source)

The 50 Major Engineering Failures (1977-2007) Part-2

April 28, 2008List of Engineering Failures Contributed by Material Failures, Corrosion, Design Flaw, and Construction Defect in Oil and Gas Production Facilities, Hydrocarbon Processing, and Oil and Gas Distribution

(Part 2 of 5) - Muhammad Abduh (abduh@reksolindo.co.id)

–

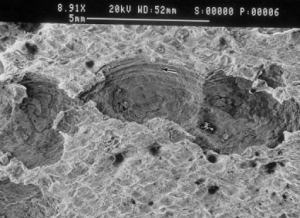

9. Piper Alpha North Sea UK – July 8, 1988 (Gas Leaking, Offshore Platform, 167 killed, US$965,000,000/1,270,000,000)

It was dominantly operation error when gas leaking from two blind flanges then gas ignited and exploded. A pump from two available pumps was tripped, and an operator inadvertently changing the backup pump with pressure relief valve that had been removed for maintenance. Severity damage of the explosion was due to large part the contribution of oil and gas pipelines connected to Piper Alpha. While the platform was in fire two other platform Tartan and Claymore continued pumping gas and oil. (Source 1,2, Video)

10. Antwerp Belgium – March 7, 1989 (Fatigue/Weld Failure, Petrochemical Plant, US$ 77,000,000/99,000,000)

Explosion is believed initiated from a hairline crack in welded seam of piping at the aldheyde column. Ethylene oxide escaped from the leak, formed polyethylene glycol (PEG) in the insulation material and accumulated for a period of time. Sequential explosion was believed by the chemical mechanism inside the insulating material and PEG. The explosion caused extensive damage to the plant and it was closed for at least 24 months with total business interuption cost up to US$ 270,000,000. (Source, Location)

11. Richmond California US – April 10, 1989 (Weld Failure, Refinery, 8 injured,US$87,170,000/112,000,000)

Failed line carrying hydrogen gas caused a high pressure hydrogen fire and resulted in flame impingement to calcium silicate insulation of the hydrocracker reactor skirt. The reactor which was 10 to 12 feet in diameter and wall thickness of seven inches failed subseqently. The reactor was in maintenance cycle for hydrogen purging. It is believed that leaking started from a failed elbow of 2-inch line at 3,000 psi. (Source, Location)

12. Baton Rauge Louisiana US – December 24, 1989 (Brittle Fracture, Refinery,US$ 68,900,000/89,000,000)

The record for low temperature (10 oF and 700 psi) at the region is believed as the major contributor to the failure of 8-inches pipeline carrying gas mixture of ethane and propane. After few minutes of vapor cloud was ignited and piperack containing 70 lines ruptured subsequently. Also with two storage tanks containing 3,600,000 gallons and 12 small tanks containing 882,000 gallons of lube oil also contribute to subsequent fire. (Source, Location)

13. Coatzacoalcos Mexico – March 11, 1991 (Pipe Leaking, Petrochemical Plant,US$ 91,300,000/112,000,000)

Gas leaking from pipe rack lead to explosion. The first explosion occured and caused additional damage to the pipe rack. Second explosion was more powerful and could be felt more than 15 miles from the facility creating damage to offsite third party facility. The explosion and fire made this vinyl chloride plant, a significant output for Mexico national demand, shut down for seven months. (Source, Location)

14. Dhaka Bangladesh – June 20, 1991 (Weld Failure, Petrochemical Plant, US$ 71,000,000)

The fertilizer plant which was constructed in 1970 suffer significant damage due to an explosion. The failure of a welded joint between carbondioxide stripper and main cylindrical body resulted in the release of high pressure gas which consisted of ammonia, carbon dioxide, and carbamate liquids. (Source)

15. North Rhine Germany – December 10, 1991(Erosion-Corrosion, Refinery, US$ 50,500,000/62,000,000)

A Pipe failed at T-junction in hydrocracker unit resulted in hydrocarbon and hydrogen release. The release of the gas ignited and explosion occured and made severe damage to the hydrocracker unit and adjacent substantial part of the plant. The hydrocracker unit was shut down for seven months. The failure of the pipe was contributed by erosion-corrosion due to plant aging. (Source)

16. Guadalajara Mexico – April 22, 1992 (Corrosion, Fuel Pipeline, 206 killed, 500 injured, 15,000 evacuated, US$ 300,000,000)

Guadalajara, Mexico second largest city, experienced series of ten massive explosion that equals to 7,0 richter scale from fuel pipeline blast. An investigation into the disaster revealed that the most possible cause for the explosion was the interference of fuel pipeline with new water piping system. The fuel pipeline was carbon steel and the sewer system was zinc-coated copper. These two lines were close enough to interfere each-other. Three days before the explosion, there were complaints from the city residents

about gasoline-like smell coming from the water pipe and sewer system. (Source 1, 2, Location)

17. Westlake Louisiana US – July 28, 1992 (Weld Failure/Corrosion, Petrochemical Plant, US$ 25,000,000/30,000,000)

A reactor vessel in urea manufacturing unit exploded. The force of the explosion could be felt in areas up to 10 miles from the plant. The fragmented shell of the column propelled up to 900 feet from their original location. The reactor was constructed 25 years earlier with 90 feet tall and 6 feet in diameter. The shell consisted of 4-inches laminations including 3/8 inches stainless steel liner. The explosion resulted from carbamate leaking at the inside vessel. Improper weld on a bracket supporting a tray inside the reactor created carbamate leak and subsequent corrosion and containment of the vessel. (Source, Location)

18. Wilmington California US – October 8, 1992 (Erosion-Corrosion, Refinery, US$ 73,300,000/96,000,000)

An explosion initiated from hydrogen processing unit. Sequential fire and explosion occured to hydrocracker unit, and hydrode sulfurization. The explosion could be felt approximately 20 miles from the plant. The explosion made the plant operator reduce production capacity to 50 percent from its normal 75,000 barrels per-day. It took 8 months to recover the production capacity. The explosion resulted from ruptered carbon-steel-elbow suffering locally thinning due to long term erosion-corrosion. (Source, Location)

19. Sodegaura Japan- October 16, 1992 (Fatigue, Refinery, 10 killed, 7 injured, US$ 160,500,000/196,000,000)

An explosion from failed heat exchanger in the hydrode-sulphurization unit caused hydrogen release and ignited fire and explosion. Technical investigation to the failure noted a complexity of the failure mechanism. The cause of the failure initiated by repetition of variation of temperature lead to decrease of diameter gasket retainer and bending deformation of rock ring. These events contributed to break out of rock ring and made spouts hydrogen gas. (Source, Location)

20. La Mede, France November 9, 1992 (Pipe Leaking, Refinery, US$ 260,000,000/318,000,000)

A pipe failed at T-junction in hydrocracker unit resulted in hydrocarbon and hydrogen release detection. Subsequent fire and explosion caused severe damage to FCC unit, gas plant, control room, and two new process unit under construction. The explosion also causing offsite damage nearby residential within the radius of 6 miles away. The business interuption loss due to this accident is estimated at US$ 180,000,000. (Source, Location)

21. Baton Rouge Louisiana US – August 2, 1993 (Creep, Refinery Plant, USD 65,200,000/78,000,000)

An elbow in the feed line of coker unit ruptured when feed switching were performed. Other pipes in unit ruptured subsequently releasing more hydrocarbons and fueling more fire to the plant. Because of the accident the coker unit was shut down for three weeks. Investigation to the failed elbow noted that carbon steel elbow was wrong material chosen with less creep resistance instead of 5Cr alloy steel.

22. Simpsonville Sacramento US- June 6, 1996 (Pitting Corrosion, Fuel Pipeline, USD 27,000,000/33,000,000)

An aboveground pipe segment failed by corrosion releasing 22,800 barrels of diesel fuel. The pipe manufactured in 1962 with 36-inches in diameter, 0.28-inches in thickness, and has specified maximum yield strength (SMYS) 52 kpsi. The pressure of pipe at the time of failure was 399 psi, the designed maximum pressure was 803 psi. (Source)

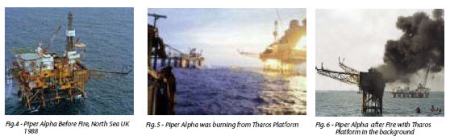

23. Rio Piedras San Juan Puerto Rico – November 21, 1996 (Wrong Material in HCA, Gas Distribution Pipeline, 33 killed, 69 injured, USD 5,000,000)

Polyethylene pipe transporting propane gas to consumer was failed leading to fire and explosion. The explosion occurred in five stories full occupied business center at shopping district Rio Piedras San Juan Puerto Rico. The leaking of plastic pipe was believed due to construction excavation damage around the pipeline. More than 20 pipes and conduits surrounding the plastic pipe which were being constructed, being used and had been abandoned. Construction excavation damage to plastic pipe was rather unavoidable and there should be pipeline design with higher integrity within high consequence area (HCA) like Rio Piedras shopping district. (Source)

–

No comments:

Post a Comment