Troubleshooting and maintenance of GC Systems

Troubleshooting a GC chromatograph can be made easier, if one learns to

recognize the symptoms produced by an instrument malfunction, column and

detector problems, leaks. Many symptoms appear as unusual peaks as

shown below:

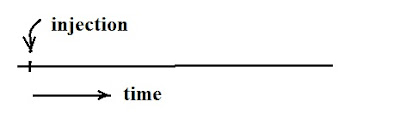

Symptom: No peaks (Fig. 1)

|

| Fig. 1: No peaks appear after the injection of the sample |

Possible Cause:

Main power off, fuse burned out

Action: Plug in the instrument,

replace fuse

Possible Cause:

Detector off

Action: Turn detector on and adjust

its sensitivity

Possible Cause: No

carrier gas flow

Action: Check the carrier gas lines

and correct the problem i.e. replace empty gas cylinders, possible obstructed

or broken gas lines

Possible Cause:

Injector temperature too low. The sample is not vaporized

Action: Increase injector

temperature.

Possible Cause:

Injector septum is leaking

Action: Replace the septum.

Possible Cause:

The syringe used for the injection of sample is plugged up.

Action: Clean the syringe or replace

it if it is damaged.

Possible Cause:

The FID flame is out.

Action: Check the FID flame. Check

if water vapor condenses on mirror. Light up the flame if needed.

Possible Cause:

Column connections are loose.

Action: Check for leaks. Use a leak

detector. If needed tighten column connections

Possible Cause:

Oven temperature too cold. Possibly, the sample condenses in the column

Action: Increase oven temperature

Symptom: Retention

times or areas are not reproducible (Fig. 2)

Possible Cause:

Septum is leaking

Action: Replace the septum if it is

damaged. If there is a premature septum failure (less than 200 injections)

check also if:

The syringe needle is not straight

The syringe is not installed

correctly

The septum retainer nut is too tight

Possible Cause: Syringe

is dirty or damaged

Action: Replace the syringe if it is

damaged. Clean the syringe with an appropriate solvent if it is dirty.

Possible Cause: Sample

is not stable under the conditions of the analysis

Action: Check the sample stabiblity.

Some samples change with heat or U.V. light. In case the sample is

photosensitive use amber sample vials.

Possible Cause: Sample

volume is too low or too high

Action: Check the sample vials. If

the sample vials are not filled correctly, evaporation or contamination may

affect the analysis. The sample level should be approximately half the volume

of the vial.

Symptom: Poor

sensitivity with normal retention time

Possible Cause: Insufficient

sample size

Action: Increase sample size. Check

syringe needle for plugging.

Possible Cause: Poor

sample injection technique

Action: Check if the proper

injection technique is used.

Possible Cause: High

attenuation

Action: Reduce attenuation.

Possible Cause: FID

response low

Action: Optimize the flow rates of H2

and air. Use N2 for make-up gas

Possible Cause: Thermal

conductivity response low

Action: Use higher filament current.

Possible Cause: Syringe

or septum leaking when injecting

Action: Replace syringe and/or

septum

Symptom: Poor

sensitivity with increased retention time and broadening of the peak

Possible Cause: Carrier

gas flow rate too low.

Action: Increase carrier gas flow.

Possible Cause: Septum

is leaking.

Action: Replace septum.

Symptom: Irregular baseline

drift (isothermal)

|

Fig.4: Irregular baseline drift when operating isothermally

|

Possible Cause: The

instrument location is not according to the manufacturer’s specifications .

Action: Instrument should not be

placed directly under heater or air conditioner or any other place where it is

subject to excessive drafts and ambient temperature changes.

Possible Cause: Column

packing bleeding.

Action: Let column to stabilize as

described by the manufacturer.

Possible Cause: Carrier

gas leaking.

Action: Locate leaks and correct.

Possible Cause: Carrier

gas regulators do not work properly.

Action: Check carrier gas regulators

and flow controllers.

Possible Cause: Poor

air or H2 regulation (FID detectors)

Action: Check regulators and flow

controllers.

Possible Cause: Detector

is contaminated

Action: Clean detector according to

manufacturer’s specifications. Raise temperature and bake out detector

overnight.

Possible Cause: Detector

filaments are defective (TCD detector only)

Action: Change the filaments.

Symptom: Contamination

or ghost peaks

Possible Cause: Vial

cap septum is dissolving in solvent

Action: Check the vial septum. If it

is not resistant enough to the solvent you are using try a more resistant type.

Possible Cause: Injection

port septum is giving off volatiles

Action: Make several blank runs with

a small piece of aluminum foil backing the inlet septum. If the contamination

peaks disappear, they were probably due to the septum. Use another type of

septum that is stable to the required injector temperatures.

Possible Cause: Column

is contaminated

Action: Examine the first 10 cm of

the capillary column for contamination holding a light behind it. If possible

cut the contaminated part of the column. Replace or clean the inlet liner.

Possible Cause: The

sample is not stable

Action: Store the sample in a

protected environment and use amber sample vials.

Symptom: Sinusoidal baseline

drift

|

Fig.5: Sinusoidal baseline

drift

|

Possible Cause: Oven

temperature defective

Action: Replace the oven temperature

sensing probe .

Possible Cause: Oven

temperature control was set to a low value

Set the oven temperature control to

a higher value.

Possible Cause: Carrier

gas flow regulator defective

Replace the carrier gas flow

regulator. Set to a higher pressure in order to stabilize the gas flow.

Possible Cause: Carrier

gas cylinder pressure too low to allow regulator to work properly

Replace the carrier gas cylinders.

No comments:

Post a Comment